Sludge Removal In Biofloc

Anaerobic decomposition needs space. Sludge collection set up 242 Sludge incubation for biofloc development.

Higher Nitrogen And Phosphorus Immobilization In Bioflocs Is Associated With Higher Temperature And Increased Suspended Solids In Shrimp Farming With Biofloc Technology Pimentel 2020 Aquaculture Research Wiley Online Library

Detachable bottle was cooled using ice cubes to minimize sludge decomposition by bacteria.

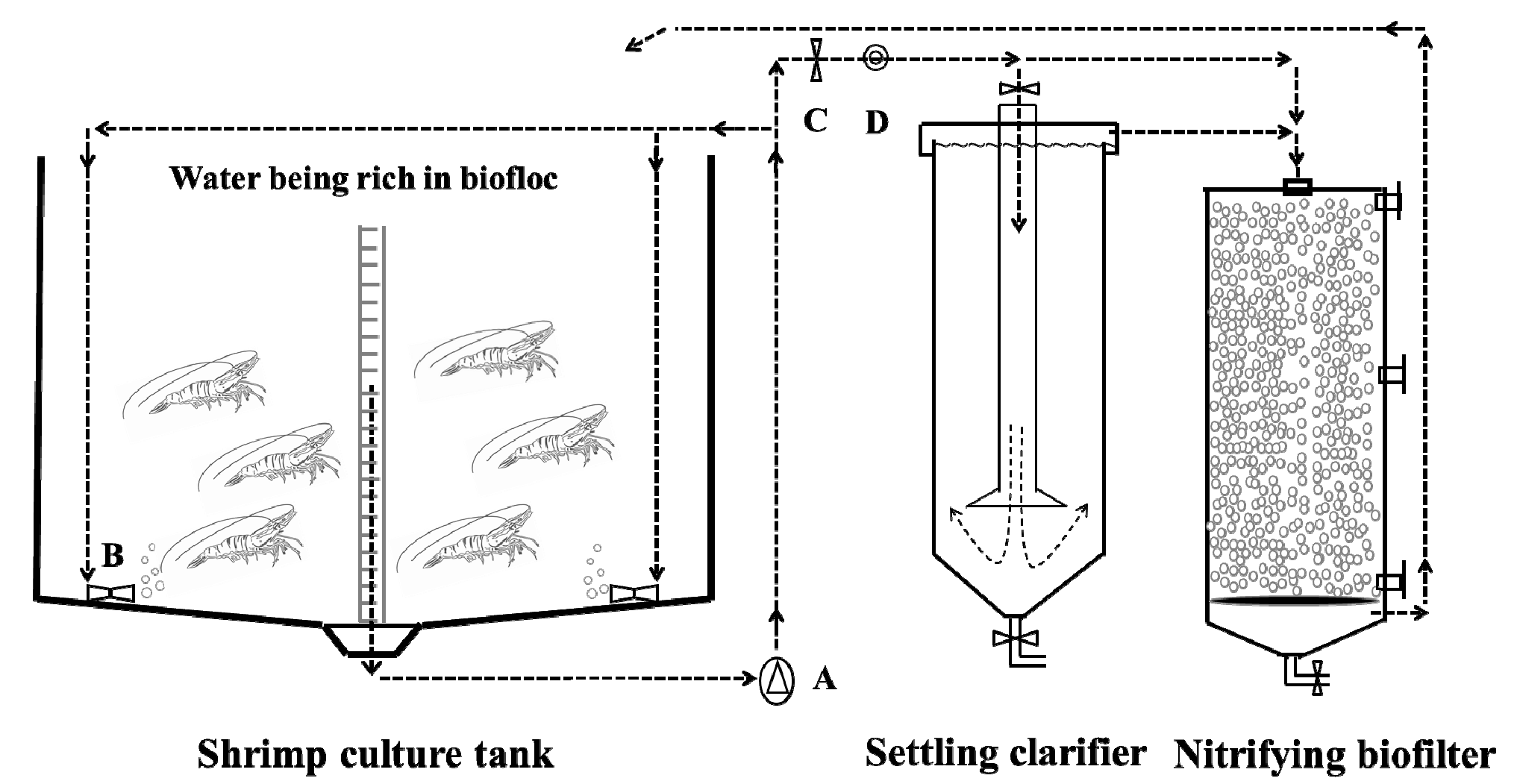

Sludge removal in biofloc. A water flow of 7 Lmin was maintained over each tank. The main goal of culture filtration is the removal of nitrogen waste usually in the form of toxic ammonia. Floc volume should be in the 5-50 mLL range.

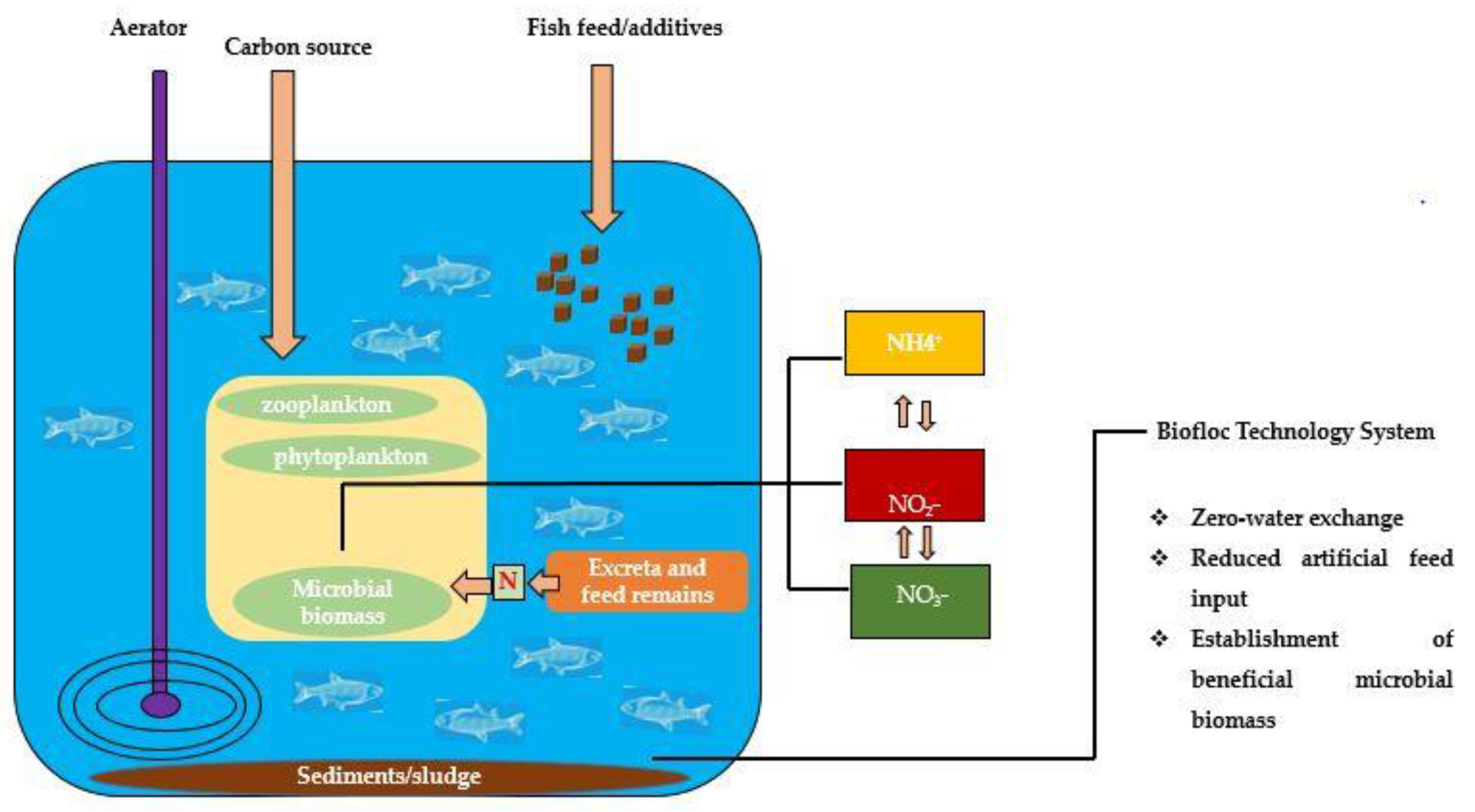

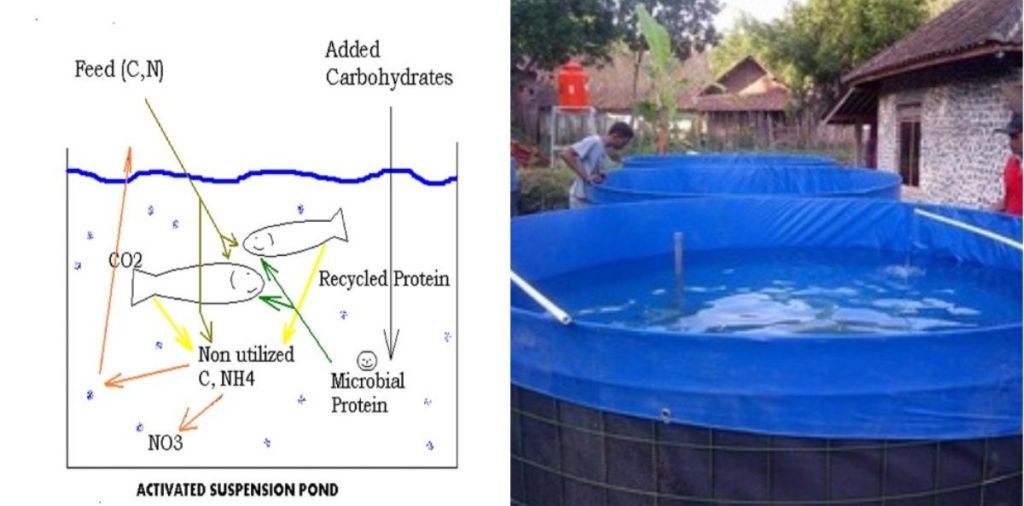

One way to remove the excess biofloc concentration produced is to use settling chambers Ray et al 2010. The sludge removal facility SRF is a circular depression constructed in the middle of the pond that is an enhanced version of the traditional center drain said Estilo. Up to 10 cash back This paper describes the potential valorization of sludge waste generated from aquaculture using biofloc system for bioremediation purpose.

If it is too low add carbohydrates and if it is higher than 50 increase sludge removal. Sludge from collectors was then carefully transferred to the incubation reactors and divided equally among the reactors. Removal of excess sludge.

Near market production for freshlive supply Zero exchange farms can be located away from saline water sources. Due to the vigorous aeration and agitation necessary for a biofloc It has been shown that a biofloc system can produce more shrimp system many of the solids from shrimp faeces and uneaten feed per unit area of more than 25 tonnesha compared to conventional are kept in suspension thereby reducing sludge accumulation and shrimp farming many of which produce less than 15 tonnesha. Three sets of mesocosms were artificially contaminated by 5 of crude oil vv representing a control inoculated mesocosm with a commercial hydrocarbonoclastic consortia and a treatment that correspond to the use of sludge from floc-forming.

An example of this would be emptying a settling basin sporadically. In the case of an increase of nitrite carefully check for sludge piles and if found change aerator deployment. An alternative solution to both problems is biofloc production in a unit external to the farm in an activated sludge system for effluent treatment.

Determination of floc volume using Imhoff cones is easy and cheap. In simple anaerobic decomposition sludge forms in some portion of the system is allowed to go anaerobic for a short period of time and then is removed from the system. The main source of ammonia is protein digestion either by the culture animals directly or the microorganisms feeding on the fish or shrimp waste.

Bioflockolkatabioflocindiabioflocwestbengalbiofloctrainingkolkatabioflocliveharvestingin this video we are talking about a revolutionary air lift techni. BIOFLOC TECHNOLOGY IN FARMS Biofloc enhancement and control Aeration techniques Sludge removal techniques INDOOR GROW OUT TECHNOLOGY Compact production systems Year round dailyweekly harvest capabilities. Although this practice produces sludge an organic rich effluent Fontenot et al 2007 Ray et al 2011 Schveitzer et al 2013.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. At this stage. Since the biofloc system is a zero-water exchange system we constructed a sludge removal facility to remove the sludge or pond waste that has accumulated in the shrimp rearing pond.

Ammonia itself can be used as a food source by autotrophic bacteria.

Water Free Full Text Characteristics Of Ammonia Removal And Nitrifying Microbial Communities In A Hybrid Biofloc Ras For Intensive Litopenaeus Vannamei Culture A Pilot Scale Study Html

Biofloc Sludge Removal System With Advanced Filter Without Water Exchange Youtube

Crude Protein And Lipid From Biofloc Meals From An Activated Sludge System Global Aquaculture Advocate

Shrimp Farming Biofloc Technology Shrimp Farming Fish Farming Systems Biology

Performance And Microbial Community Analysis Of Combined Denitrification And Biofloc Technology Cdbft System Treating Nitrogen Rich Aquaculture Wastewater Sciencedirect

Biofloc Fish Farming Sludge Remover Filter Making Video Youtube

Table 4 From Biofloc Management With Different Flow Rates For Solids Removal In The Litopenaeus Vannamei Bft Culture System Semantic Scholar

Biofloc Catfish Growth Ll Sludge A Problem But No Solution Ll Rsm Biofloc Fish Farming Training C Ll Youtube

Bioavailability Of Crude Protein And Lipid From Biofloc Meals Produced In An Activated Sludge System For White Shrimp Litopenaeu Retratil Toldo Retratil Toldo

Biofloc L How To Remove Sludge From Biofloc Tank L Biofloc Airlift System For Sludge Remove L Sludge Youtube

Https Www Mdpi Com 2073 4441 12 11 3000 Pdf

Crude Protein And Lipid From Biofloc Meals From An Activated Sludge System Global Aquaculture Advocate

Airlift Technique To Remove Sludge And Filtration System To Improve Water Quality In Biofloc Tank Youtube

Sustainability Free Full Text Biofloc Systems For Sustainable Production Of Economically Important Aquatic Species A Review Html

Biofloc L How To Remove Sludge From Biofloc Tank L Biofloc Airlift System For Sludge Remove L Sludge Youtube

Ten Easy Steps Towards Biofloc Production Of Shrimp Or Tilapia The Fish Site

Biofloc Improves Water Effluent Quality And Growth Parameters Of Penaeus Vannamei In An Intensive Culture System Sciencedirect

Biofloc Technology Bft In Aquaculture India A Full Guide Agri Farming

Biofloc Systems Fish Pond Shrimp Farming Fish Farming

Post a Comment for "Sludge Removal In Biofloc"